Braun Personal Lift Corporation FMVSS No. 403 Bedienungsanleitung Seite 2

- Seite / 8

- Inhaltsverzeichnis

- LESEZEICHEN

Bewertet. / 5. Basierend auf Kundenbewertungen

Braun Corporation FMVSS No. 403 Quick Reference Installation Sheet 32553 Rev. A

VEHICLE

BO

X FRAME

VEHICLE

CHASSI

S MEMBER

2

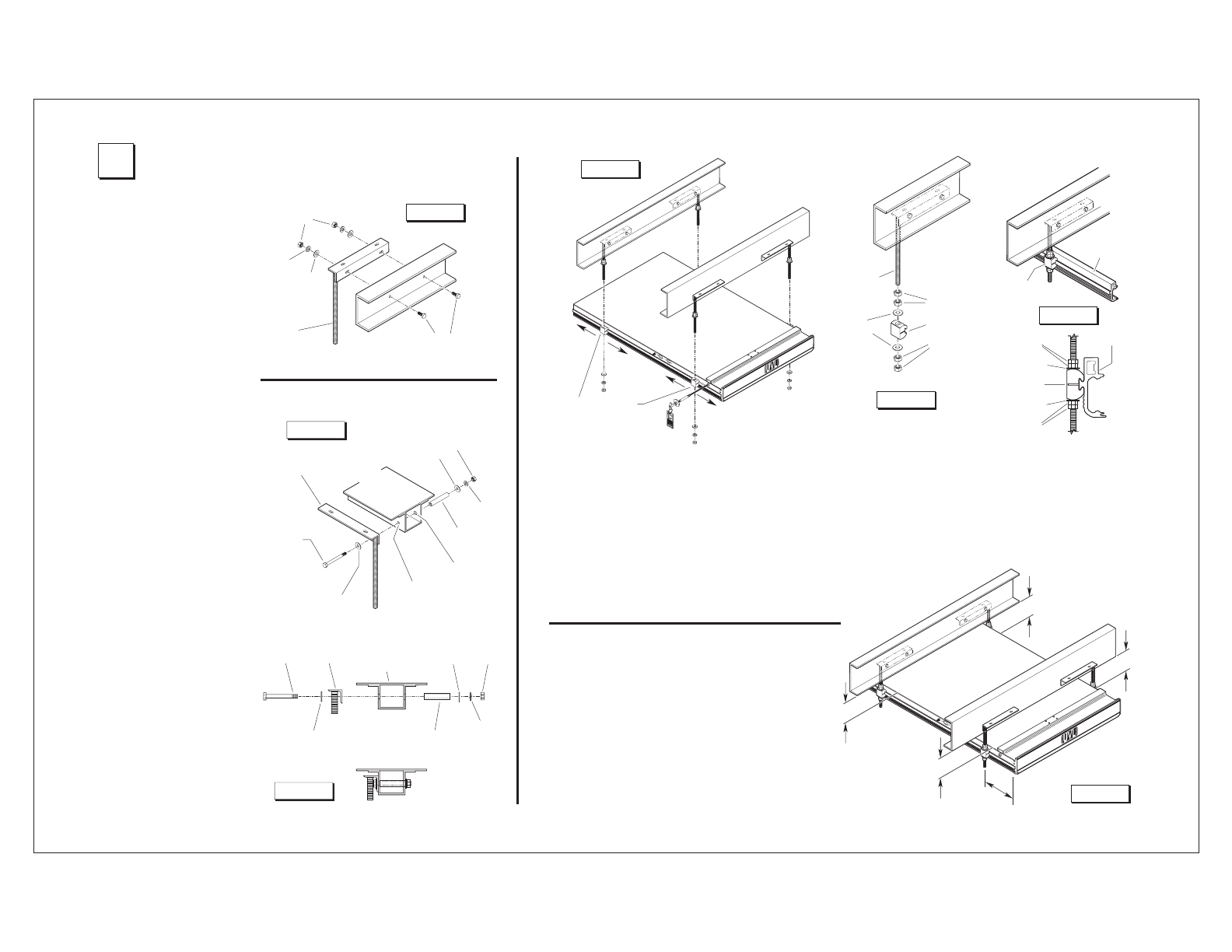

Secure Lift

Attach Mounting Brackets to

Vehicle Frame

Mounting bolts must be routed

horizontally through the verti-

cal face of the “L” brackets and

framing members as shown in

Figures D, E and F.

Eight 3/8-16 x 1-1/2" hex bolts

are supplied for bolting the all-

thread mounting brackets to the

frame (two per bracket). Oval

slotted mounting holes are pro-

vided in the mounting brackets

to allow adjustment. Carefully

drill 25/64" (.390") diameter

mounting holes at the center of

the oval mounting slots.

Channel Frame Applications:

Secure mounting bolts as speci-

fied in Figure D.

Box Frame Spacers: Position

tubing spacers as shown at

right to prevent collapsing the

box frame. Carefully drill a

25/64" (.390") diameter mount-

ing hole through one side of the

box frame. Drill a 5/8" (.625")

diameter hole through the

opposite side of box frame to

allow installation of spacer. Cut

spacer tubing to length (equal

to thickness of box frame).

Note: A longer 3/8-16 bolt will

be required for box frame appli-

cations. Secure mounting bolts

as specified in Figures E and F.

All fasteners must meet FM-

VSS 571.403 Section 6.3.

“Box” Framing Member

“Channel” Framing Member

3/8-16 x 1-1/2"

Hex Bolt

All-Thread

Bracket

Box

Framing

Member

Spacer

Flat

Washer

Lock

Washer

Hex

Nut

Flat Washer

3/8-16

Hex Bolt

3/8-16 x 1-1/2"

Hex Bolt

Flat

Washer

Lock

Washer

Hex

Nut

All-Thread

Bracket

Spacer

Flat

Washer

Lock

Washer

Hex

Nut

All-Thread

Bracket

Flat Washer

Figure D

Figure E

5/8"

Diameter

Hole

25/64"

Diameter

Hole

“Box” Framing Member

Figure F

Assembled

Spacer Tubing

Length: Equal

to thickness of

box frame.

Shipping Block Removal:

Wood blocks are placed in the

lift housing to prevent lift dam-

age during shipment. Remove

shipping blocks from platform

and carriage before running

(activating) lift. Refer to

Shipping Block Removal

Instruction 28942.

W

A

R

N

I

N

G

8

1

8

2

3

P

u

sh

T-

h

and

l

e

i

n

f

u

l

l

y

and

m

a

n

u

a

l

l

y

m

o

v

e

p

l

a

t

f

o

rm

i

n

a

n

d

o

u

t

t

o

en

g

a

g

e

pl

a

t

fo

r

m

l

o

ck

b

e

f

o

r

e

d

r

i

v

i

ng

v

eh

i

c

l

e

.

F

ai

l

u

r

e

t

o

l

o

ck

p

l

a

t

f

o

rm

m

a

y

r

es

u

l

t

i

n

u

n

i

n

t

e

n

d

ed

p

l

a

t

f

o

rm

d

ep

l

o

y

men

t

.

U

n

i

n

te

n

d

ed

p

l

a

t

f

o

r

m

d

e

p

l

o

y

m

ent

m

a

y

r

e

sul

t

i

n

s

e

ri

o

u

s

b

o

d

i

l

y

i

nj

u

r

y

a

n

d

/

o

r

p

r

o

per

t

y

da

m

a

g

e

.

D

o

n

o

t

r

e

m

ov

e

!

VEHI

CLE

CHASSIS MEMB

ER

VEHI

CLE

CHASSI

S MEMB

ER

Align mounting clamps

with all-thread studs.

Position and secure lift.

Thread two 3/4" hex jam nuts fully

onto each mounting bracket all-thread

stud. Place one large diameter flat

washer onto each all-thread stud (use

tape to hold in place). See Figures G

and H.

Carefully position lift under vehicle

(aligned with mounting brackets).

Position (slide) the four lift mounting

clamps along the sides of the lift hous-

ing until aligned with mounting bracket

all-thread studs. See Figure G.

Height Adjustment

The lift housing must be

aligned with vehicle chas-

sis. Adjust the 3/4" hex jam

nuts on the all-thread mount-

ing studs at all 4 corners of

the lift until dimensions A, B, C

and D are equal (within 1/16").

See Figure J.

In-Out Positioning

Position the lift to achieve a 2”

overlap between the deployed

inboard barrier and the vehicle

floor.

Figure G

Jam Nuts

Lift Clamp

Jam Nuts

All-Thread

Stud

Flat

Washer

Jam Nuts

Flat Washer

Lift Clamp

Flat Washer

Jam Nuts

Lift

Housing

Lift

Housing

Lift

Clamp

Shift lift and mounting brackets

left-to-right as needed (lift must

be centered in door opening).

Tighten the 3/8" bolts securing

mounting brackets to the frame.

Torque Specifications: 25 to 30

foot pounds.

Figure H

Figure I

Figure J

Note: The two outboard mounting

brackets should be positioned a

maximum of 16” from the end of the

cassette. See Figure J.

Carefully raise lift into position as high

as possible (height adjustment outlined

below). Place one large diameter flat

washer onto each mounting bracket all-

thread stud. Thread two 3/4" hex jam

nuts fully onto each all-thread stud (up

against lift mounting clamp).

VEHI

CLE

CHASSIS MEMB

ER

VEHICLE

CHASSIS MEMBER

A

B

C

D

16”

Max

imum

Dimensions

A, B, C and D

must be equal

(within 1/16

").

Tighten upper set of 3/4" hex

jam nuts (with flat washer)

down to the lift mounting

clamps. Tighten jam nuts.

Torque Specifications: 100

to 120 foot pounds.

(6 Seiten)

(6 Seiten)

(95 Seiten)

(95 Seiten) (19 Seiten)

(19 Seiten) (41 Seiten)

(41 Seiten)

Kommentare zu diesen Handbüchern